Recognizing Membrane Layer Bioreactors: The Future of Wastewater Therapy

Membrane layer bioreactors (MBRs) represent a noteworthy development in the area of wastewater treatment, integrating biological processes with advanced membrane layer filtering to boost effluent quality. As international water scarcity and rigorous governing frameworks become significantly pushing problems, MBR technology uses a reliable reaction through its capability to reduce impact and optimize source healing. Nonetheless, the adoption of MBRs is not without its obstacles, which warrant cautious consideration. What are the key factors affecting their application and long-term viability in various contexts? The responses may improve our approach to wastewater monitoring.

What Are Membrane Bioreactors?

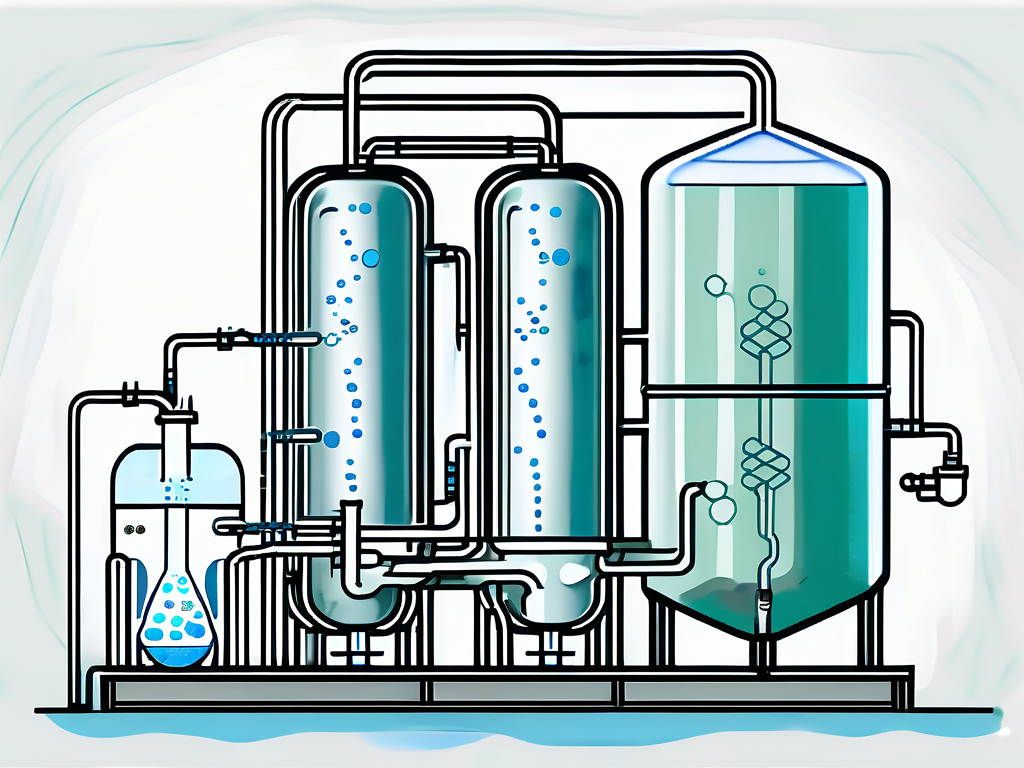

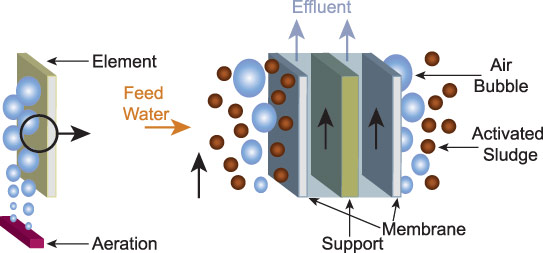

The core components of MBR systems consist of a bioreactor where microbial task takes place and a membrane layer system that filterings system the combined liquor. This dual functionality enables the synchronised deterioration of raw material and solid-liquid separation in a solitary action. MBRs can operate in both submerged and external arrangements, with immersed systems being a lot more common as a result of their portable design and functional effectiveness.

The adoption of MBR technology has actually obtained traction in various applications, varying from local wastewater treatment to industrial effluent monitoring. MBRs are especially useful in situations where room is restricted or strict effluent high quality criteria should be satisfied. By maintaining a high focus of microorganisms within the bioreactor, MBRs improve the destruction of organic contaminants, thereby producing greater therapy efficiencies compared to standard methods.

Secret Benefits of MBR Technology

The integration of organic therapy with membrane layer purification in MBR systems supplies countless benefits that set it besides conventional wastewater therapy techniques. One of the key advantages is the enhanced effluent high quality. MBRs efficiently eliminate suspended solids and pathogens, accomplishing higher levels of purification that meet rigid discharge standards and facilitate water reuse applications.

Another substantial advantage is the lowered sludge manufacturing. MBR systems produce much less excess sludge, causing lower disposal expenses and a decrease in environmental impact. The closed nature of the membrane system decreases the risk of smell emissions and enhances general procedure control.

Lastly, MBRs are functional and versatile, making them ideal for different wastewater kinds, consisting of commercial and community sources. The capacity to incorporate with advanced therapy innovations additionally boosts their performance, making MBRs a promising service for the future of wastewater administration.

Difficulties and Limitations of MBRs

While MBR technology offers countless benefits, it additionally encounters numerous obstacles and constraints that can influence its prevalent fostering. One considerable difficulty is the high funding and operational costs connected with MBR systems. The first investment for membrane layer products and the required infrastructure can be substantial, making it much less easily accessible for smaller districts or markets.

Furthermore, membrane fouling continues to be a critical concern that can lessen system efficiency and increase maintenance needs. Fouling happens when solids, natural matter, or microbes gather on the membrane surface area, leading to minimized leaks in the structure and requiring constant cleaning or substitute.

One more constraint involves the complexity of the modern technology. MBR systems require skilled workers for procedure and upkeep, which can be an obstacle in regions with limited technical proficiency. Moreover, the disposal of invested membranes provides ecological problems, as the products are often not naturally degradable and can contribute to lose monitoring difficulties.

Finally, while MBRs can successfully treat a vast array of wastewater, they may not be suitable for all applications, particularly those with high focus of fats, oils, and greases, necessitating more research study and innovation to attend to these limitations.

Applications of Membrane Layer Bioreactors

In different industries, membrane layer bioreactors (MBRs) have arised as a versatile option for wastewater treatment (Membrane Bioreactor). Their applications extend community, commercial, and agricultural setups, showcasing their adaptability and effectiveness in varied environments. In local wastewater therapy plants, MBRs dramatically enhance effluent high quality, permitting water reuse and lowering the environmental effect of released wastewater

Industrially, MBRs are employed in food and beverage handling, fabric production, see and pharmaceutical manufacturing, where they effectively treat high-strength waste streams. Their capacity to handle differing and rising and fall tons impurity focus makes them specifically important in these industries. Furthermore, MBRs assist in the elimination of virus, suspended solids, and raw material, contributing to compliance with strict discharge policies.

In agriculture, MBRs are increasingly used for treating farming drainage and animals wastewater, allowing the healing of nutrients for fertilizer manufacturing. They also aid in the therapy of greywater for irrigation, promoting sustainable water administration methods.

The adaptability of MBRs is additional evidenced by their assimilation with other technologies, such as anaerobic food digestion and advanced oxidation procedures, improving overall efficiency and resource healing in wastewater treatment systems.

The Future of Wastewater Treatment

Advancements in modern technology and a growing focus on sustainability are shaping the future of wastewater treatment. Membrane layer bioreactors (MBRs) exemplify this change by integrating address organic treatment processes with membrane layer filtration, causing premium effluent suitable for reuse. The pattern towards round economies is triggering centers to take on MBRs for their ability to recuperate sources, such as water and nutrients, from wastewater.

Innovations in membrane layer materials and arrangement are boosting the performance and longevity of MBR systems, decreasing functional costs and power consumption. Smart innovation assimilation, consisting of real-time tracking and automated control systems, is additional optimizing performance and making it possible for anticipating upkeep, thus lessening downtime.

Moreover, societal assumptions and governing stress are pushing municipalities and industries to adopt even more sustainable techniques. Membrane Bioreactor. The shift in the direction of decentralized wastewater treatment solutions is gaining grip, permitting localized therapy that decreases transportation prices and power usage

Conclusion

Membrane layer bioreactors (MBRs) represent a transformative approach to wastewater therapy, integrating organic procedures with advanced membrane layer innovation. The advantages of MBRs, including boosted effluent quality, decreased spatial requirements, and reduced sludge production, place them as a practical option amidst growing urbanization and stricter ecological guidelines. Regardless of existing difficulties, the continued advancement in membrane layer materials and operational approaches promises to reinforce the effectiveness and fostering of MBRs, ensuring their critical role in the future of lasting wastewater administration.

Membrane bioreactors (MBRs) represent a significant technology in the area of wastewater therapy, incorporating organic procedures click to find out more with innovative membrane layer filtering to improve effluent top quality.Membrane layer bioreactors (MBRs) combine biological treatment procedures with membrane layer filtering to successfully deal with wastewater.The combination of biological treatment with membrane layer purification in MBR systems supplies many advantages that establish it apart from traditional wastewater therapy techniques. Membrane bioreactors (MBRs) exemplify this shift by incorporating organic treatment procedures with membrane layer purification, resulting in high-grade effluent ideal for reuse.Membrane bioreactors (MBRs) represent a transformative approach to wastewater therapy, integrating organic procedures with advanced membrane innovation.